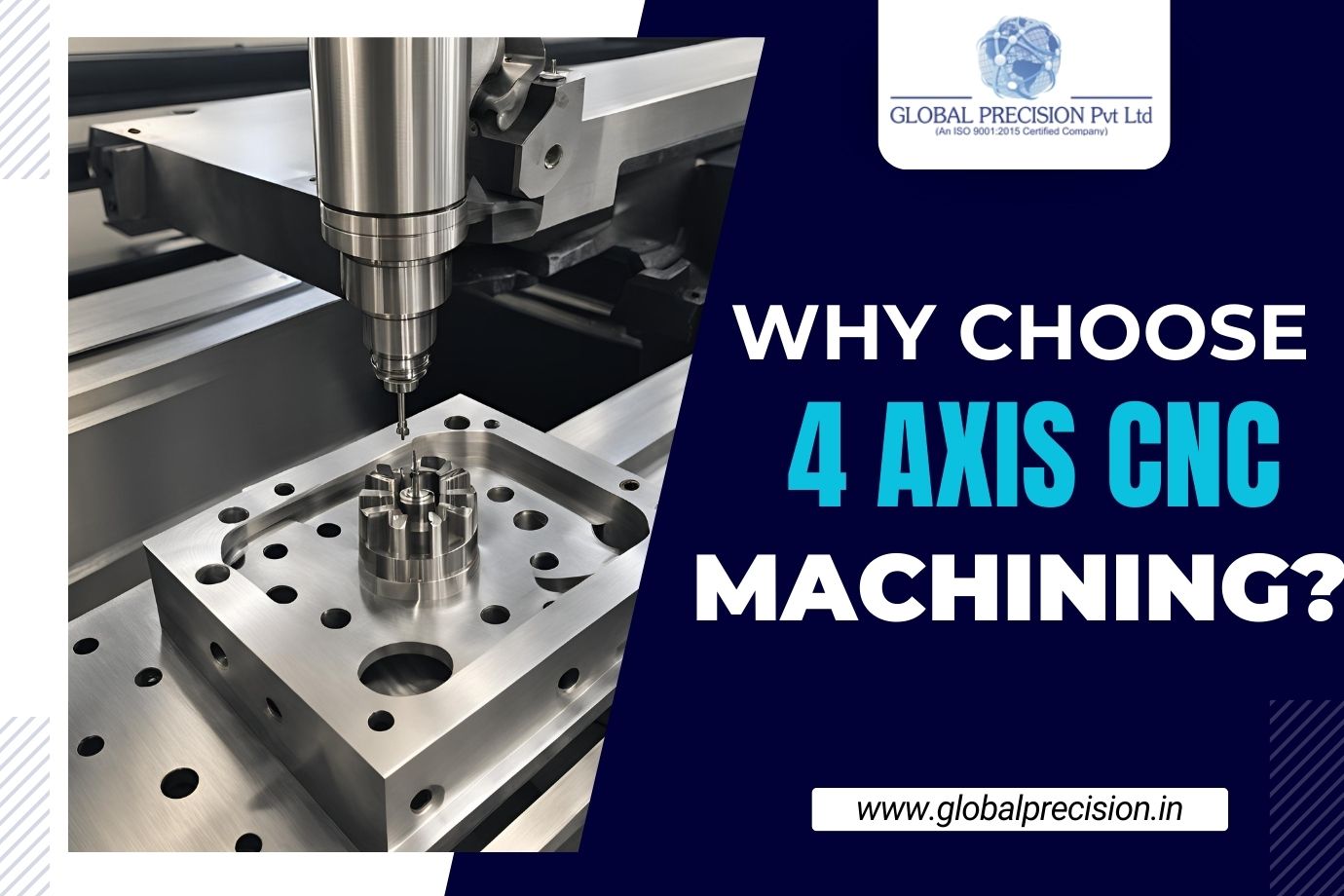

Nowadays, companies need to be productive, accurate, and flexible to succeed. When we talk about cutting-edge machining methods more and more businesses are turning to 4 Axis CNC (Computer Numerical Control) machining. This tech lets companies do trickier machining jobs while saving time and money making it a big step up from the usual 3-axis machines.

At Global Precision Pvt Ltd, we focus on 4th Axis VMC (Vertical Machining Center) machining providing a broad set of services to meet our clients’ changing needs. This article will look into the upsides of 4 Axis CNC machining and explain why you should pick it for your manufacturing work.

What is 4 Axis CNC Machining?

4 Axis CNC machining adds another direction of movement to the usual three axes (X, Y, and Z). In a 3-axis machine, the cutting tool moves along these three straight lines to shape the part. But the 4th axis brings in a spinning motion often around the X-axis. This lets the cutting tool work on many sides of the material without having to move the workpiece by hand.

This extra freedom has an impact on the variety of machining options. It allows people to make more intricate and detailed parts with fewer setups and better accuracy.

Key Advantages Of 4 Axis CNC Machining:

1. Increased Flexibility and Versatility

4thAxis VMC machining has a big plus: it is flexible. The extra 2th axis spins the workpiece letting the tool reach the material from many angles. This means you can make trickier shapes, like curves, holes, and pockets, without taking out and moving the workpiece.

Whether you need VMC job work to make detailed designs or super-precise parts, 2 Axis CNC machining gives you the range to handle all sorts of projects. From planes to cars many industries use it to make complex parts that need machining on multiple sides.

2. Improved Precision

In making top-notch parts, accuracy is key. 4 Axis CNC machining boosts accuracy as the machine can tackle multiple sides of the material at once. This cuts down on human mistakes since there’s no need to move the workpiece by hand. The non-stop machining leads to tighter fits and fewer differences, which matters a lot when making vital parts like 4th Axis VMC machining components for fields such as electronics and healthcare.

For industries that need complex parts with exact sizes, 4 Axis VMC job work offers the level of accuracy needed to meet tough standards.

3. Time and Cost-Efficiency

4 Axis CNC machining cuts down on machining time. This has a positive impact on efficiency. The 4th axis lets the workpiece rotate so fewer setups are needed. In old-school 3 axis machining, you must move the workpiece by hand to machine a new side. This wastes time and might cause things to be out of line.

On the other hand, 4th axis VMC Machining cuts down on idle time, which speeds up production. This makes manufacturing faster and cuts costs by needing fewer hours. At Global Precision Pvt Ltd, we aim to provide effective answers that shorten production time and expenses. Our goal is to deliver top-notch results without breaking the bank.

4. Ability to Handle Complex Geometries

4 Axis CNC machining lets you create intricate shapes that 3-axis machining can’t make. The 4th axis gives better access to hard-to-reach parts of the workplace. This solves issues with parts that need work on many sides or have complex details.

For instance, industries that need parts with curved or spherical surfaces will find 4 Axis VMC job work essential. The 4th axis makes the machining process more flexible, whether you are creating complex prototypes or making small batches of precise parts.

5. Increased Production Capacity

4 Axis CNC machining speeds up production and reduces setups, which boosts output. Companies can handle more projects while keeping quality high. This helps businesses grow and meet higher demand without sacrificing precision or effectiveness.

At Global Precision Pvt Ltd, we use 4th-axis VMC machining to complete large production jobs. We meet tight deadlines and keep quality consistent for all parts.

Applications Of 4 Axis CNC Machining:

Many industries use 4-Axis machining, including –

- Aerospace – To make turbine blades, engine parts, and other complex items.

- Automotive – Making details parts like gears, pistons, and other pieces that need high accuracy

- Healthcare – Creating medical tools and implants that require careful and exact cutting.

- Electronics – To produce small complex parts used in gadgets and machines.

- Prototyping – Great for making test versions with complex designs before starting full production.

4 Axis CNC machining helps makers create top-notch complex parts across many industries.

Why Pick Global Precision Pvt Ltd For 4 Axis CNC Machining?

At Global Precision Pvt Ltd, we take pride in giving top-notch 4th Axis VMC machining components and job work to meet our client’s growing needs. Here is why you should pick us to handle your machining tasks –

- Cutting-edge Equipment – We use advanced 4 Axis CNC machines that deliver the highest levels of precision and flexibility. Our top-notch equipment allows us to tackle even the trickiest machining jobs with ease.

- Expert Team – Our team of skilled professionals has expertise in VMC Job work. We have worked in this field for years making sure every project fulfills high standards for accuracy and gets done.

- Customized Solutions – We know each project is different so we offer solutions that fit your specific needs. Whether you need 4 Axis VMC job work for small or big production runs, we can adjust our services to match what you are looking for.

- Commitment to Quality – At Global Precision Pvt Ltd, quality is central to all we do. We use strict quality checks to make sure every part we make first meets your exact requirements.

- Cost-effective Services – We aim to offer machining solutions that would not break the bank but still deliver top-notch results. Our efficient methods and cutting-edge equipment enable us to keep prices competitive. This makes us a great fit for companies seeking dependable and budget-friendly machining services.

Conclusion

4 Axis CNC Machining has revolutionized manufacturing. It gives more benefits than old 3-axis machines. These include better flexibility, higher precision, and faster production. Companies that want to make complex parts with high accuracy and low costs should choose this method.

Global Precision Pvt Ltd focuses on 4th Axis VMC machining components. We make sure our clients get top-quality parts that fit their needs. Our cutting-edge tech and expert team can help you. Whether you need detailed prototypes or large-scale production, we are ready to support your goals.

Pick Global Precision for your 4 Axis CNC Machining jobs and see how precise, effective, and affordable they are right away!