The requirement for high-quality, precision-manufactured parts has never been higher. One innovation that has fundamentally changed manufacturing methods in industries around the world is the technology of CNC machining.

Computer Numerical Control (CNC) machining is essential to the production of precision, reliability, and efficiency in producing parts needed by manufacturing institutions and processes. As industries continue to evolve, CNC machined parts appear to be the future of manufacturing and are revolutionizing how products are designed and made.

Here, we will explore why CNC machined parts represent the future of manufacturing, the benefits of CNC machined parts, and how companies such as Global Precision Pvt Ltd are assisting in advancing this disruptive technology.

Table of Contents

What Are CNC Machined Components?

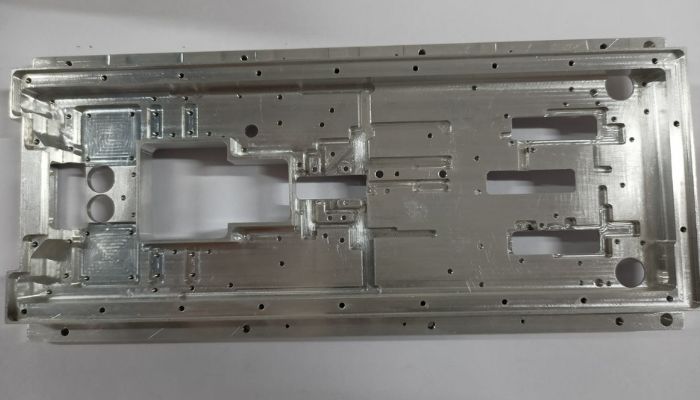

CNC machined components refer to parts and products that are produced using computer numerical control technology. CNC machining consists of the computer-automated control of machining tools, including lathes, mills, drills, and others. The process is exceptionally accurate, enabling manufacturers to fabricate components with complex designs and tight tolerances.

With CNC machining, every aspect of production is automated, from the cutting of raw materials to the production of complex shapes. This results in consistency and accuracy, even in the production of larger quantities of parts. CNC machined components can be applied to various industries, such as medical devices, aerospace, automotive, electronics, and many others.

The Advantages Of CNC Machined Components:

The transition towards the use of CNC machining in the manufacturing sector can be attributed to the multitude of advantages it provides. As such, CNC machined parts have witnessed an increase in popularity and are being recognized as the new future of manufacturing.

- Precision and Accuracy

A primary benefit offered by CNC machining is precision. CNC milling components are fabricated with meticulous accuracy, down to fractions of a millimeter. Precision is of utmost importance in highly technical applications including but not limited to aerospace applications and medical device manufacturing, as any single error can result in unacceptable failure. Therefore, the features of CNC machining correspond directly to the manufacturing of parts with extreme precision.

- Consistency in Production

For a mid-sized CNC machined components manufacturers like Global Precision Pvt Ltd., CNC machining allows for as much automation as possible, in order to produce the same output consistently, across each and every part. With manual machining, output can vary significantly, especially in the case of producing large volumes. However, CNC machines produce the same product and can maintain consistency with no variations whatsoever across manufacturing production levels.

- Versatility and Complexity

CNC machining can produce components from a variety of materials, including metals, plastics, wood, composites, and other types of materials. This diversity allows manufacturers to create components that are used in various industries. As an example, intricate CNC turned components are used in automotive assembly. Similarly, precision medical devices can be manufactured through CNC machining as well as other complex components. The fact that complex designs can be produced utilizing CNC machining allows manufacturers to broaden their production capabilities and serve customers more effectively.

- Cost-Efficiency

Despite the cost of CNC machines may seem high as a starting investment, consider the benefits of labor cost savings, a significant reduction in waste, and overall production efficiency when using an automated process. CNC components manufacturers can then choose to socialize these savings to their end customers with the result of a lower high-quality component. In addition, with CNC machines, there is a reduced risk of human error resulting in further savings through reduced defective products and reduced open CNC component production or wasted materials.

- Faster Turnaround Times

The production of CNC machined components development and manufacturing takes place in a much shorter time frame in comparison to traditional machining processes. After the design is processed into the machine, it will run nonstop, and produce the components in a fraction of the time. A fast turnaround is essential for industries that require a high volume of parts, with time constraints. CNC machining will get the product to the market faster without affecting quality as CNC machining helps to satisfy demand.

- Reduced Waste

CNC machining is the most efficient material. The CNC process for milling components is fully automated and utilizes the raw materials efficiently without creating excess waste. Conventional machining, prior to advanced cutting methods programmed into CNC machines, creates waste because of human errors and cutting methods wasting materials. These components are designed to determine the most economical use of raw materials, reducing waste while increasing sustainability.

How CNC Machining Is Revolutionizing Industries:

The influence of CNC machining within the manufacturing field is significant. It is changing aspects of manufacturing and other industries alike through faster, more efficient, and more reliable production.

- Aerospace Industry

When it comes to aerospace, precision is critical. Any CNC machined component ensures that each and every part will adhere to the extremely high standards of performance and safety required for airplanes. In some cases, parts such as engine pieces and landing gear assemblies are incredibly complex and require multiple uses of CNC machining to create reliable and precise components.

- Automotive Industry

In the automotive industry, CNC turned components are simply everywhere, manufacturing engine parts and transmission components among many other components.

In the automotive industry, one of the best parts of CNC machining is that thousands if not millions of parts are made quickly, effectively, and with consistent quality. CNC machined components mean that each part will fit correctly, enhancing the performance and safety of passenger vehicles.

- Medical Devices

Medical devices require precise and sterile components. CNC machining is the best and most efficient manufacturing process to create complicated parts for use in surgical instruments, implants, and diagnostic equipment. Accurate and repeatable CNC machining are both important for medical devices to perform reliably.

- Electronics

There is a growing trend of miniaturization of components in electronics. CNC machined components are key to producing small and complex parts found in smartphones, computers, and other electronic devices. The accuracy of CNC machines allows for incredibly small and precise components to be produced.

Global Precision Pvt Ltd: Leading The Way In CNC Machined Components

Global Precision Pvt Ltd has emerged as one of the leading manufacturers of CNC components despite its modest range of products, which speaks to its expertise in manufacturing high-quality CNC machined components for various industries. Utilizing state-of-the-art CNC milling machines and skilled engineers to meet the quality and precision necessary to build its products, any customer’s standards will be successfully achieved via every product manufactured at Global Precision Pvt Ltd.

Global Precision Pvt Ltd is an object-oriented, professional, and quality product provider of CNC components, with a long-standing consideration for its customer’s satisfaction. Its high-grade CNC components are produced in a wide range of CNC components including CNC turned components to more complex CNC milling components; all to satisfy the range of component needs. Whether it is parts unique to the aerospace industry or custom parts produced for medical devices, Global Precision Pvt Ltd will have the parts uniquely tailored to ongoing customer and industry needs.

As a leading CNC components manufacturer, Global Precision Pvt Ltd understands the demands of the dynamic CNC machining profession. Global Precision Pvt Ltd intends to stay on the leading edge of CNC machining technology, continually investing in the latest tool and technique methods as an added value to the ongoing changes needed by clients.

Conclusion

CNC machined components are changing the landscape of manufacturing in terms of precision, efficiency, and cost. As industries continue to look for better quality, dependability, and usefulness, CNC capabilities will continue to shape the landscape of the future. These are allowing components to be produced in a variety of markets with better accuracy and consistency, such as automotive to medical devices.

Companies like Global Precision Pvt Ltd are leading the way, by specializing in providing top quality CNC turned components and CNC milling components for all industries. As the manufacturing landscape changes, CNC machined components will remain the leaders in new products and efficiencies throughout an array of industries.

If you’re searching for precision engineered manufacturing, partnering with a reputable manufacturer of CNC machined components is essential to success in the current competitive landscape.