The automotive manufacturing industry is growing rapidly, with the industry’s progress reliant on the advances within the field of precision engineering. Technology enables transformation, and technology-driven automotive manufacturers are producing vehicles that are safer, more efficient, and greener. Precision engineering, or manufacturing processes that achieve a high level of accuracy, will facilitate this evolution. Let’s discuss how the future of auto manufacturing is being reshaped by precision engineering and highlight the impact of companies like Global Precision Pvt Ltd, a leading Precision Machined Components Manufacturer, that delivers top-notch Precision Machined Components.

Table of Contents

The Changing Landscape Of Auto Manufacturing

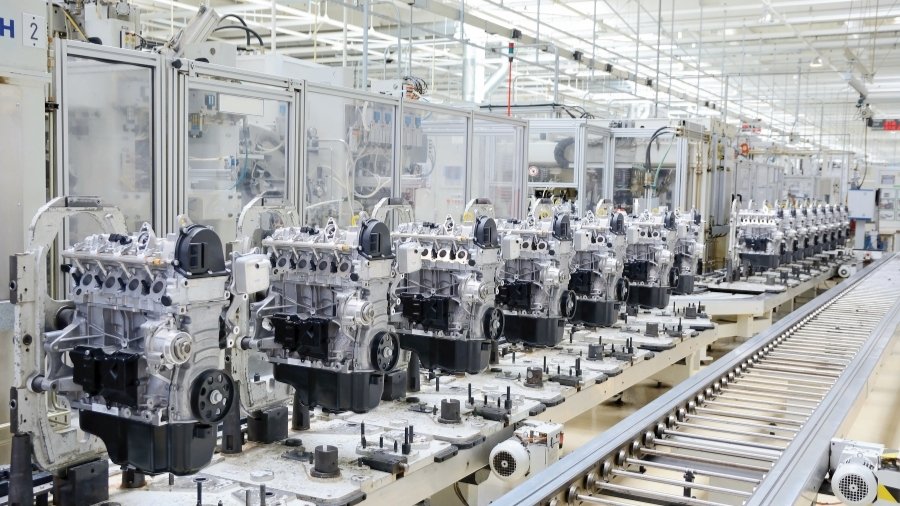

Over the years, the auto manufacturing industry has changed considerably. The industry has transitioned from utilizing traditional assembly line techniques to employing automated, computer-controlled processes that produce more recursive vehicles. This transformation is driven solely by consumer demand to achieve performance, improved safety, and eco-friendliness in a vehicle. Today’s auto manufacturers are using technology to address those demands. They are utilizing robotics, artificial intelligence, and precision engineering in their production activities.

The Role Of Precision Engineering

Precision engineering is focused on creating parts with very high levels of accuracy and very tight tolerances. In automotive manufacturing, that means that every part of the vehicle, whether it’s an engine part, chassis part, or part relating to the transmission, is made exactly to specifications. These precision manufactured components are very important to the overall quality and performance of automobiles. When parts fit together precisely, the vehicle will operate in a more efficient, reliable, and durable way.

For example, Precision Machined Components are the reason vehicle engines run smoothly, and automatic and manual transmissions shift as intended. When every small part is manufactured at a high precision, it will add to the overall safety and longevity of the vehicle. Precision engineered parts will also help ensure each component meets a certain quality standard, limiting the overall defects of the assembled vehicle, and improving the overall product performance.

Advantages Of Precision Engineering In Auto Manufacturing

1. Enhanced Safety.

Vehicles today must meet strict safety standards. Precision engineering ensures that every component functions correctly, reducing the risk of accidents due to part failure. With high-quality Precision Machined Components, auto manufacturers can produce vehicles that perform reliably even under extreme conditions.

2. Improved Efficiency

Manufacturing optimization results in enhanced engine performance, reduced fuel utilization, and decreased emissions. Tighter tolerances on parts improve performance, which is especially important today when environmental considerations matter more. Automotive manufacturers can benefit from precision engineering because it allows them to build vehicles that are compliant but also exceed public expectations for efficiency.

3. Cost-Effective Production

While the up-front cost of acquiring a precision engineering machine or technology can seem expensive, in the long run, it will have the opposite effect: lower waste and maintenance costs. By using precision machining, fewer errors occur, which saves rework costs. This is significant for manufacturers who supply Precision Machined Components Manufacturer because these two aspects may be the most important factors in staying competitive as you serve the international market.

4. Customization And Innovation

Interest in personalized transport is on the rise. Accuracy engineering enables businesses to create bespoke vehicle components that satisfy specific customer needs. Companies like Global Precision Pvt Ltd are staying ahead of the competition with their unique offering of Precision Machined Components that satisfy specific design and performance specifications. This enables more imaginative vehicle designs and options to satisfy the growing demand of a wider consumer group.

Global Precision Pvt Ltd: A Leader In The Field

In the competitive environment of auto manufacturing, having someone to rely on for dependable, high-quality components is crucial. Global Precision Pvt Ltd has become a leader in precision engineering, producing high-quality Precision Machined Components that leading automotive manufacturers around the world use. With their precision machining expertise, they can satisfy modern automotive manufacturers’ stringent specifications to ensure each component can perform and reliably function.

As a leading manufacturer of precision machined components, Global Precision Pvt Ltd uses state-of-the-art CNC technology and automated systems to manufacture parts that are consistent and precise. Their dedication to quality and innovation not only meets the current needs of the auto industry but leads the way for future applications. By continuing to invest in research and development, Global Precision is leading the next generation of automotive design and manufacturing.

The Future Trends In Auto Manufacturing

Looking ahead, several trends are expected to shape the future of auto manufacturing –

- Electrification of Vehicles – The emergence of electric vehicles (EVs) is currently among the foremost trends in the automotive business. Precision engineering is crucial in creating high-performance batteries, electric motors, and control systems to electrify vehicles. Quality components will ensure that the end product operates safely and effectively.

- Automation and Smart Manufacturing – Automation is expected to dominate more aspects of auto manufacturing. Smart factories that leverage AI and robotics will achieve faster production cycles, lower costs, and better quality control. Precision engineering will be a prominent part of these automated processes, ensuring all components are manufactured to precise specifications.

- Sustainability and Green Manufacturing – Environmental issues have increased the importance of sustainability to auto manufacturers. Precision engineering contributes to more effective manufacturing processes, which translates into less waste and energy consumption. As companies strive to build greener vehicles, precision machined parts will continue to play an important part in meeting standards for sustainable products.

- Customization and Advanced Materials – Consumers are looking for vehicles that fit their tastes and needs. Developments in precision engineering make the design and manufacture of custom components that can improve a vehicle’s performance and appearance. The development of advanced materials will also help deliver lighter, stronger, and more durable parts to the mix; pushing further the limits of automotive design.

Conclusion

The prospect of auto manufacturing is optimistic as the incorporation of precision engineering is permeating every phase of manufacturing. Components produced through high-quality precision machining are integral to this enhancement by allowing manufacturers to develop vehicles that are safe, efficient, and invigorated with innovation. Because the industry is constantly changing, the significance of Components Manufacturers specializing in Precision Machined Components, like Global Precision Pvt Ltd, becomes increasingly essential. Manufacturers of precision machined components understand the high quality of the products that they offer and deliver high-tolerance products that satisfy the needs of the modern auto industry while providing a peek at advancements yet to come.

The reputation of auto manufacturers as state-of-the-art companies focusing on new technologies in precision engineering puts them at an advantage in addressing what awaits them in the near future. The partnership of automation, advanced materials, and customizable solutions takes us to a time when vehicles are more reliable and environmentally friendly, and consumers have many options tailored specifically to their needs. The manufacturers that make these precision engineered choices, today, will be the leaders shaping and defining what auto manufacturing looks like in our future.