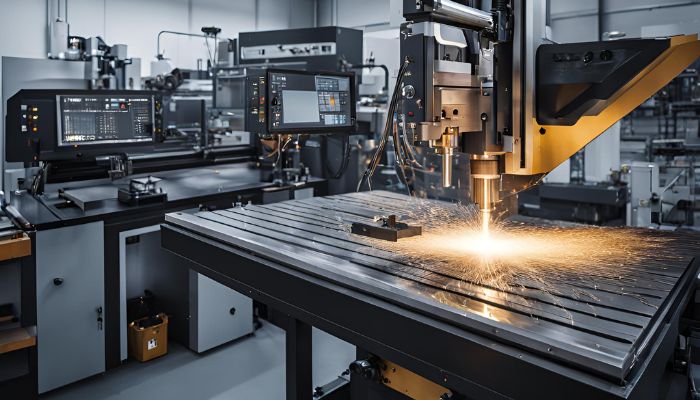

The inception of CNC and VMC machined components has brought a great revolution in modern manufacturing. From aerospace to automotive, these modern machining components are contributing significantly by offering high precision, efficiency, and versatility.

A VMC and CNC components manufacturer, through the implementation of VMC and CNC machining techniques, can manufacture high-precision engineering components efficiently with the least risk of injuries and exposure to hazards.

This blog will shed more light on CNC and VMC machined components with a complete guide featuring differences, components, and applications of these modern machined components.

Table of Contents

An Overview Of CNC (Computer Numerical Control) Machining:

CNC machining is an advanced manufacturing process that involves CNC machines that carry out a wide variety of tasks, ranging from basic drilling and cutting to intricate 3D shaping. CNC machines can be defined as automated tools or machinery that perform precise functions by comprehending the commands of pre-programmed software. The software that gives instructions to the CNC machines for performing exact movements and tasks is programmed by using CAD and CAM programs.

An Overview of VMC (Vertical Machining Center) Machining:

VMC machining is also an advanced manufacturing process; unlike CNC machines, this type of process uses VMC to perform a variety of machining operations and produce a variety of complex machinery parts. VMC machines use the same technology as CNC for getting instructions; however, they’re more precise than CNC machines in performing different operations. They’re significantly helpful in manufacturing parts with unusual and complex shapes.

Differences between CNC and VMC Machining:

All VMC machines are CNC machines, as they use a CNC system to control their movements and machining operations. But there are important distinctions between the two in terms of their versatility, materials, orientations, etc.

1. Spindle Orientation: CNC machines used by CNC components manufacturer can feature both types of spindle orientation, horizontal and vertical. VMC machines always have a vertically oriented spindle that holds the cutting tool.

2. Materials: Both types of modern manufacturing machines can work with a wide range of materials, including aluminum, steel, brass, titanium, plastic, metal composites, etc. However, CNC machines are preferred for softer materials, including brass, plexiglass, wood, acrylic, etc. VMCs, with their unique vertical spindle orientation, provide stability and precision for working with hard materials like aluminum and steel.

3. Versatility: The major difference between the two is that CNC machines are general-purpose and VMC machines are more specialized. Drilling, cutting, 3D shaping, and multi-axis machining are some of the applications of CNC machines. VMC machines are especially suited for vertical milling tasks and the production of precise and detailed parts.

4. Setup: CNC machines feature a flexible setup and can be applied to several components. Whereas VMC machines have a more specific setup and are best for vertical cutting tasks.

5. Machining Speeds: VMC machines have low RPM, which fosters a high metal removal rate and more aggressive cuts. However, CNC machines feature higher RPM, which leads to lighter cuts and longer machining times.

Core Components Of CNC and VMC Machines:

CNC machines used by a CNC components manufacturer feature several components. Among some core components are; a control unit that interprets instructions; a spindle that holds and rotates the workpiece during machining; driving systems that feature motors that are responsible for the movement of the tool along the axes; a worktable; a display unit; and others.

Similar to CNC machines, VMC machines also feature several components, including a vertical spindle that holds the cutting tool, X, Y, and Z axes of motion, a CNC control system, a coolant system that cools the cutting tool or workpiece to prevent overheating and extend the tool’s life, a driving system, a tool changer mechanism, a worktable that supports the workpiece during machining, a chuck, a spindle taper, and others. The spindle orientation and various axes of motion allow a VMC components manufacturer to perform more precise operations.

Materials Used in CNC and VMC Machining:

The correct selection of material is very crucial. While selecting machining material, you can consider factors like mechanical properties, machinability, cost, operating environment, etc.

- Commonly Machined Metals: Stainless steel, aluminum, copper, brass, steel, titanium, and bronze are common metals that are used for CNC and VMC machining. Their special properties like high strength, machinability, excellent electrical conductivity, etc. make them suitable for CNC and VMC machining manufacturing.

- Non-metallic Materials: CNC and VMC machines are also used with different non-metallic materials, like different types of plastics such as ABS, PTFE, PMMA, Polycarbonate, Nylon, etc. Additionally, foam, ceramics, and wood can be utilized.

Applications of CNC and VMC Machined Components:

These modern machining techniques are used in diverse industries, including:

- Automotive: From engine blocks to suspension components, CNC machines are used to manufacture a variety of automotive components. VMC machines are equally important for this industry and are used in the manufacturing of flanges, connectors, gears, pulleys, brackets, etc.

- Aerospace: Parts of spacecraft, satellites, aircraft, and different aerospace applications are manufactured by using CNC and VMC machines.

- Medical: In the medical and pharmaceutical industry, these advanced machining techniques greatly contribute to manufacturing surgical instruments, prosthetics, implants, etc.

- Electronics: From sockets and connectors to other complex parts of electronics, there are several electronic components manufactured by CNC and VMC machining.

- Defense, marine, woodworking, and construction are some other industries in which these modern machining techniques are used.

Conclusion:

The modern manufacturing industry strongly relies on CNC and VMC machined components because they offer unmatched accuracy, productivity, and adaptability. Choosing the right materials, designing for manufacturing, and maintaining strict quality control are essential for the creation of high-quality and stellar-performing components.

Connect with the leader of the high-precision machining and manufacturing industry, Global Precision Pvt. Ltd., to get access to cutting-edge machinery and extensive expertise. With a reputation of offering top-notch CNC and VMC machining solutions for over 12 years, we can be your right partner for exceeding specifications and adapting future-evolving manufacturing strategies.