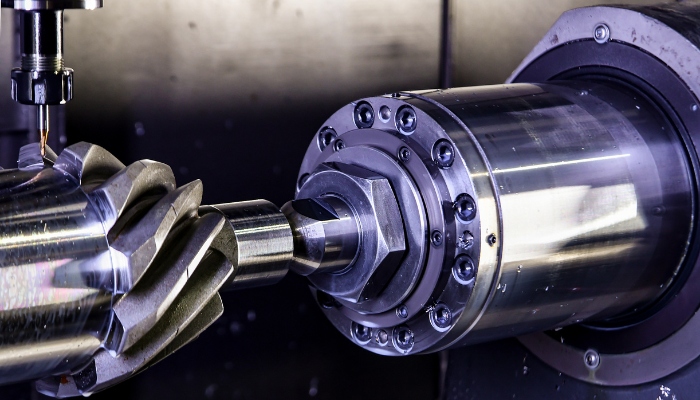

CNC machining is an extreme manufacturing technique that creates precise parts for a variety of industries. From aerospace to automotive and medical to consumer electronics, CNC machining is the backbone of modern production. For manufacturers and engineers, understanding the limitations, design principles, and values of CNC machining part dimensions is essential to achieving the desired outcomes.

At Global Precision Pvt Ltd, we pride ourselves as leading CNC machined components manufacturers providing high-quality parts tailored to meet our clients’ unique needs. Our expertise spans CNC Turned Components, CNC Milling Components, and other complex machined parts.

Table of Contents

Limitations of CNC Machining Part Dimensions:

CNC machining offers remarkable precision, but it’s important to understand its inherent limitations –

1. Size Constraints

Machines have a limited workspace, which determines the maximum size of parts that can be machined. For instance –

- A CNC milling machine may handle components up to 1000mm in size.

- CNC lathes may handle parts with specific diameter and length constraints.

2. Material Constraints

Certain materials like superalloys and hard metals may challenge CNC tools. While Global Precision Pvt Ltd specializes in machining diverse materials, it’s crucial to match material properties with tool capabilities for optimal results.

3. Tolerances

Tight tolerances are achievable but can increase production costs and time. Typical CNC machining tolerances range from ±0.01mm to ±0.1mm, depending on the part’s complexity.

4. Complex Geometries

While CNC machines can create intricate designs, extreme complexity may require specialized setups or multi-axis machines. This adds time and price to the procedure.

Design Considerations For CNC Machined Components:

Designing parts for CNC machining requires balancing functionality, manufacturability, and cost-effectiveness. Here are key design principles –

1. Simplify Geometries – Avoid overly complex shapes when possible. Simple designs are more comfortable, quicker, and more affordable to manufacture. At Global Precision Pvt Ltd, we work with clients to optimize methods for effective production.

2. Uniform Wall Thickness – Varying wall thickness can lead to material warping and machining inconsistencies. Keep walls uniform to maintain structural integrity.

3. Hole and Thread Design – Avoid excessively deep holes; a depth-to-diameter ratio of 4:1 is ideal. Standard thread sizes ensure compatibility and reduce machining time.

4. Tool Accessibility – Ensure all areas of the part are accessible by the machining tools. Features that require complex tool paths can add unnecessary challenges.

5. Material Selection – Select materials fitted to the application and machining operation. Materials like aluminum, stainless steel, and plastics are broadly used because of their machinability.

Values of CNC Machining Part Dimensions:

CNC machining ensures repeatability, accuracy, and versatility. Here’s why it’s valued –

1. High Precision – CNC machining delivers unparalleled precision, crucial for industries like aerospace and medical devices. As trusted CNC components manufacturers, we guarantee precision to meet rigorous standards.

2. Scalability – From prototyping to full-scale production, CNC machining adapts to various production needs. Our CNC Turned Components and CNC Milling Components can be produced in small or big volumes.

3. Material Versatility – CNC machines handle a wide range of materials, making them appropriate for various applications. At Global Precision Pvt Ltd, we work with metals, plastics, and composites to deliver top-notch solutions.

4. Time Efficiency – With automation and rapid tool changes, CNC machining significantly reduces production times. We ensure timely delivery without compromising quality.

5. Cost-Effective Production – Despite high initial setup costs, CNC machining offers long-term cost benefits. It minimizes waste, ensures consistent quality, and reduces labor costs.

Applications of CNC Machined Components:

The versatility of CNC machining makes it essential in different industries.

1. Automotive – CNC machined components, such as gears, shafts, and engine parts, ensure reliability and performance.

2. Aerospace – High-precision parts, such as turbine blades and structural components, are critical for safety and efficiency.

3. Medical Devices – Implants, surgical tools, and diagnostic equipment rely on CNC machining for exacting standards.

4. Consumer Electronics – Enclosures, connectors, and custom parts for gadgets benefit from CNC machining’s accuracy.

5. Industrial Machinery – Custom tooling, jigs, and machine parts are efficiently produced with CNC technology.

Why Choose Global Precision Pvt Ltd?

As a leading CNC machined components manufacturer, Global Precision Pvt Ltd delivers unmatched quality and service. Here’s what sets us apart –

1. State-of-the-Art Machinery – We use advanced CNC lathes, milling machines, and multi-axis setups to handle intricate projects.

2. Expertise Across Industries – Our team serves diverse sectors, ensuring the perfect solution for every client. Whether you need CNC Turned Components or CNC Milling Components, we’ve got you covered.

3. Custom Solutions – Every project is impressive, and we prepare our processes to fulfill specific requirements.

4. Global Reach – We supply precision parts to clients worldwide, maintaining strict quality standards.

5. Commitment to Sustainability – Our manufacturing procedures prioritize waste removal and energy effectiveness.

Partner With Us:

CNC machining is a cornerstone of contemporary manufacturing, delivering unmatched accuracy, versatility, and effectiveness. By understanding the limitations, design principles, and values associated with CNC machining part dimensions, you can create components that meet the highest standards.

At Global Precision Pvt Ltd, we take pride in being a trusted CNC components manufacturer. Whether you need custom CNC Turned Components, CNC Milling Components, or other precision parts, we are here to bring your ideas to life.

Contact us today to learn more about our services and how we can support your projects. Experience the finest in quality and trustworthiness with Global Precision Pvt Ltd, your partner for precision engineering. By incorporating the right design principles and partnering with expert manufacturers like Global Precision Pvt Ltd, you can unlock the full potential of CNC machining to produce exceptional components for any industry.