In the fast-paced industrial industry, accuracy and productivity are essential. Because of its unmatched accuracy and productivity, CNC (Computer Numerical Control) turned parts have completely changed the manufacturing sector. These parts are essential to a variety of industries, including electronics, healthcare, automotive, and aerospace.

This blog explores the benefits of CNC turned components, highlighting their significance in modern manufacturing. We’ll also take a closer look at how Global Precision Pvt Ltd excels in delivering high-quality CNC turned components & parts to meet diverse industrial needs.

Table of Contents

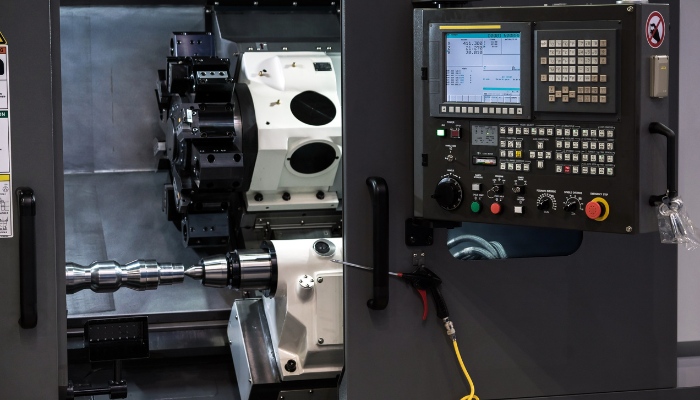

What Are CNC Turned Components?

CNC turned components are precision parts created using CNC turning machines. These machines use computerized control to rotate a material while a cutting tool shapes it. This process ensures a high degree of accuracy and consistency, making CNC turned parts an essential part of modern manufacturing.

The Benefits of CNC Turned Components in Modern Manufacturing:

1. Unmatched Precision

CNC turning machines are known for their incredible precision. They follow computerized instructions to create parts with detailed specifications, confirming that every component fulfills the required tolerances.

Industries like aerospace and medicine rely on CNC turned parts for their high accuracy. Even the smallest error can lead to product failure, making precision crucial.

2. Enhanced Efficiency

- CNC machines work fast and effectively, decreasing production time.

- Complex designs can be produced in a fraction of the time compared to manual machining.

- Continuous operation ensures high-volume production without compromising quality.

At Global Precision Pvt Ltd, efficiency is maximized using state-of-the-art technology to deliver CNC turned components & parts swiftly.

3. Consistency in Quality

CNC machines can replicate designs flawlessly. Whether producing a single part or thousands, the quality remains consistent. This repeatability is vital for industries requiring uniform components, such as automotive and electronics.

4. Cost-Effectiveness

While CNC machines involve an initial investment, they save money in the long run.

- Reduced waste – The precision of CNC machines minimizes material wastage.

- Lower labor costs – One operator can manage multiple machines simultaneously.

- Long-term durability – High-quality parts reduce maintenance and replacement costs.

5. Versatility in Materials

CNC turning machines can work with an expansive range of materials, including –

- Metals – Aluminum, steel, brass, titanium, etc.

- Plastics – ABS, polycarbonate, nylon, etc.

- Composites – Carbon fiber and other advanced materials.

This versatility permits manufacturers to cater to myriad industries and applications.

6. Complex Designs Made Simple

- CNC machines excel at creating intricate designs that would be almost unimaginable with manual machining.

- From delicate medical instruments to robust automotive parts, CNC turning achieves it all.

- The cutting-edge capabilities of CNC machines permit detailed engravings and fine finishes.

Applications of CNC Turned Components:

1. Automotive Industry

CNC turned parts are integral to the automotive sector.

- Examples – Engine components, transmission parts, and suspension systems.

- Benefits – High strength, reliability, and precision for critical vehicle functions.

2. Aerospace Industry

The aerospace industry requires elements with intense precision and durability.

- Examples – Turbine blades, landing gear parts, and fuel system components.

- Benefits – CNC turned components meet strict regulatory standards.

3. Electronics Industry

Miniature and precise components are crucial in electronics manufacturing.

- Examples – Connectors, casings, and fasteners.

- Benefits – CNC machining ensures compact yet reliable designs.

4. Medical Industry

In the medical field, accuracy and hygiene are essential.

- Examples – Surgical instruments, implants, and prosthetics.

- Benefits – CNC turned components offer biocompatibility and precision.

5. Industrial Equipment

CNC turning is vital in producing components for heavy machinery and tools.

- Examples – Shafts, gears, and couplings.

- Benefits – CNC machining ensures durability and optimal performance.

Why Choose Global Precision Pvt Ltd for CNC Turned Components?

Global Precision Pvt Ltd is a leading provider of high-quality CNC turned components & parts for various industries. Here’s why they stand out –

1. State-of-the-Art Technology – Global Precision uses advanced CNC turning machines to produce parts with unmatched precision and speed.

2. Expertise and Experience – With years of expertise, Global Precision has a profound understanding of various industrial demands.

3. Customized Solutions – Whether you require a standard part or a custom-designed part, Global Precision delivers tailored solutions.

4. Quality Assurance – Stringent quality control processes ensure that every component meets the highest standards.

5. Global Reach – As the name suggests, Global Precision serves clients worldwide, delivering reliable CNC turned components across industries.

The Future of CNC Turned Components:

CNC machining continues to grow with improvements in technology. The future holds exciting possibilities for CNC turned parts, including –

1. Increased Automation – Smart machines with AI capabilities will further streamline the production process.

2. Eco-Friendly Manufacturing – CNC machines are becoming more energy-efficient, contributing to sustainable manufacturing practices.

3. Advanced Materials – The use of CNC-turned components will increase with the introduction of new materials like lightweight metals and composites.

4. Digital Integration – Real-time monitoring and increased productivity will be made possible by integration with Industry 4.0 and the Internet of Things.

Conclusion:

CNC-turned components, which provide unmatched accuracy, effectiveness, and versatility, have become essential in contemporary manufacturing. These elements drive innovation in a variety of industries, including electronics, healthcare, automotive, and aerospace.

Global Precision Pvt Ltd has established itself as a trusted partner in delivering top-notch CNC turned components & parts, meeting the demands of a global market. Their dedication to quality and invention confirms they remain at the forefront of CNC machining.

Whether you’re a manufacturer seeking reliable components or an innovator looking for custom solutions, CNC turned parts are the key to unlocking new possibilities in modern manufacturing. Embrace the benefits of precision and efficiency with CNC technology today!