Global Precision - The Best CNC Machined Components Manufacturer

Expertise in CNC Machining

At Global Precision, our extensive experience and technical expertise in CNC machining set us apart. Our skilled engineers and technicians have a profound understanding of the intricacies involved, ensuring each component adheres to the highest quality standards. We are proud to be among the leading precision machined components manufacturers in India, committed to excellence.

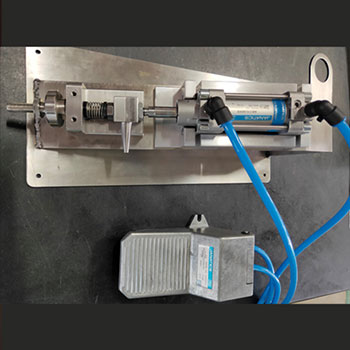

State of the Art Facilities

To deliver top-notch products, we utilize cutting-edge CNC machining equipment equipped with the latest technology. This allows us to produce best quality CNC milling components & parts with unmatched precision. Whether your project requires milling, turning, drilling, or other CNC machining processes, we are fully equipped to meet your specific needs.